GEARS FOR THERMAL & HYDEL PLANT

Gearboxes used for Thermal power plants include Worm, Helical and Bevel Helical designs. Gear systems are used extensively for running gas and steam turbine drives, turbo compressors and auxiliary starting drives.

Hydel power plants are increasingly becoming major players in providing sustainable energy. Smaller Hydel power plants require high power Hydel gearboxes.

PRODUCTS FROM RDMC

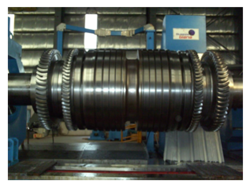

Helical Gear

Helical Gears are cylindrical gears with helicoid teeth. The angled teeth of these gears result in a gentler engagement, resulting in the gears running quieter and smoother.

Planetory Gear

Planetary Gear systems consists of one or more outer planet gears revolving around a sun gear. The planet gears are usually mounted to a movable arm which then rotates relative to the sun gear.

Rack

The rack gear is a linear shaped gear which can mesh with a spur gear. The pinion gear is a cylindrical gear which engages the teeth of the Rack gear. Together, the Rack and Pinion Gear converts the rotational motion applied to the pinion into linear motion, like turning the wheel of a car to move left or right.

Spur Gear

They are cylindrical gears with teeth arranged parallel to their axis. They are the most common type of gears available.

Sun Gear

Sun gear is typically a central mounted circular gear around which the planetary gears rotate.

They are cylindrical gears with teeth arranged parallel to their axis. They are the most common type of gears available.

Worm Shaft

The worm shaft is a cylindrical gear with meshes along the diameter, resembling a screw thread. The worm wheel is a helical gear designed to envelope the worm shaft. A Worm gear system offers a very large gear ratio in a single thread

Worm Wheel

The worm shaft is a cylindrical gear with meshes along the diameter, resembling a screw thread. The worm wheel is a helical gear designed to envelope the worm shaft. A Worm gear system offers a very large gear ratio in a single thread.